Skid Steer Snow Pusher

Built with US Steel for Skid Steers, Tractors and Loaders.

Meet the Lineup

Replacement Parts

Built for Durability

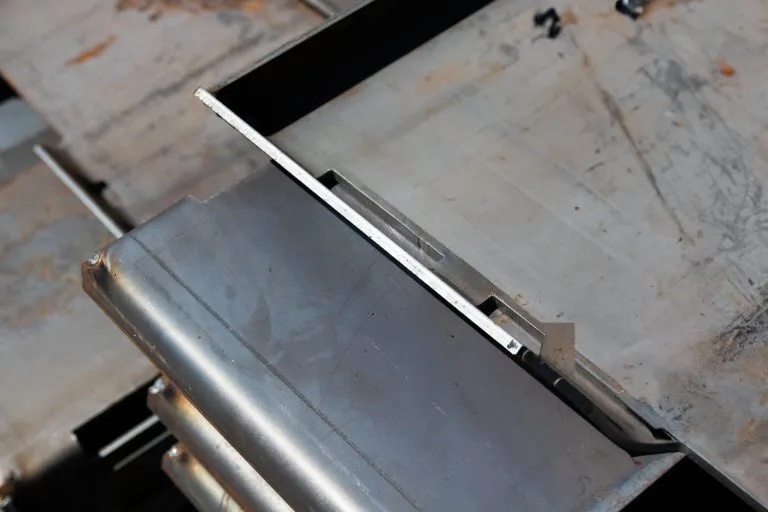

Stage 1

Steel Prep

We use a plasma cutter to cut our high-strength American steel to exact specs. Clean edges and tight tolerances set up a straight, square build.

Stage 2

Frame Fit

The moldboard, sides, and cross-bracing are dry-fit in fixtures. We confirm alignment so the pusher tracks true under load.

Stage 3

Powder Coat

Blasted, primed, and powder-coated for a lasting finish. This leaves it resistant to chips, scratches, and rust for dependable durability.

Stage 4

Final Assembly

Each unit is inspected, decals added, and prepared for shipping or available for local pickup.

XP Snow Pushers

High-Quality Equipment Built To Last

Our Craftsmanship Reflects Our Commitment To Durability And Excellence.

American Made with US Steel

Our pushers are built, painted, and shipped from our shop in Nappanee, Indiana. Using the highest quality American steel, we manufacture built-to-last snow pushers with 3/8″ sideboards and 3/16″ to 1/4″ moldboards. You can trust that it’ll be strong, durable, and ready to take on any job.

A skid steer snow pusher supports winter job sites as you can clear snow quickly, reduce downtime, and tackle large spaces. Every model we offer comes ready to attach, keeping your workflow seamless and maximizing your equipment’s potential.

Highest Quality at the Lowest Price

Understanding your need for top-notch equipment without breaking the bank, Express Steel commits to delivering excellence without the premium price tags often found with big brands. We’re all about crafting superior equipment that fits comfortably within your budget.

Just as important, our wide range of equipment also fits within your space constraints. For instance, our compact tractor snow pusher serves as a reliable solution for tight spaces or smaller commercial properties. These pushers deliver high performance without compromising on maneuverability. You’ll find them useful for light snow removal.

Quick Turn Around Times

We have pushers in-stock and ready to ship with one of our trusted carriers. We pride ourselves on quick processing and short turnaround times to get your equipment out the door and to you faster.

Custom snow pushers, pushers that include upgrades, or non-stock pushers may require some additional time for assembly.

Please reach out to our sales team to get the most accurate timeline!

What makes our Snow Pushers so popular?