Posted by Express Steel on Feb 10th 2026

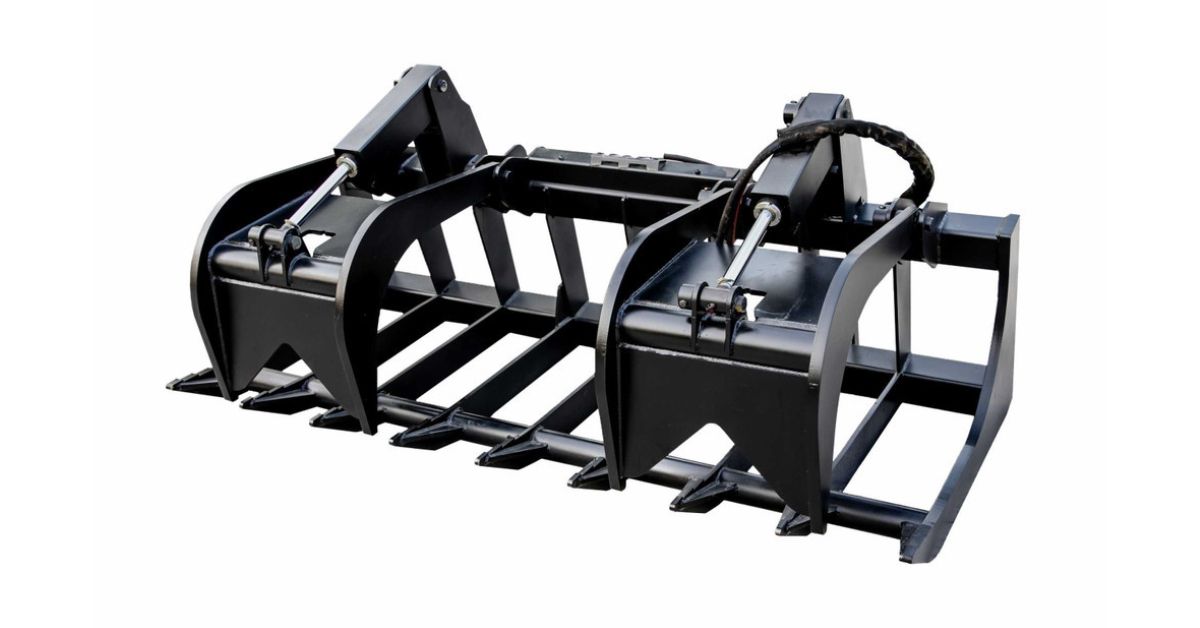

Key Benefits of Heavy-Duty Grapples for Contractors

Construction and landscaping sites demand tools that deliver raw power, precision, and reliability. Contractors constantly face the pressure of tight deadlines and difficult terrain, making the choice of equipment a critical factor in project success. Adding a heavy-duty grapple to a skid steer transforms a standard machine into a material-handling powerhouse capable of tackling the most demanding tasks. Understanding the key benefits of heavy-duty grapples for contractors allows business owners to make informed decisions that directly impact their bottom line and operational capabilities.

Driving Project Speed and Output

Time is the most valuable currency on any job site. A heavy-duty grapple significantly accelerates the pace of work by changing how operators interact with materials. Instead of using balance and gravity like a traditional bucket, a grapple employs hydraulic clamps to firmly hold unevenly shaped objects. This clamping mechanism allows the operator to move at higher speeds across uneven ground without the risk of losing the load.

Securing Loads for Faster Transport

When an operator trusts the attachment to hold the material firmly, they navigate the site with greater confidence and velocity. A standard bucket often requires the operator to drive slowly and carefully to prevent logs or concrete chunks from tumbling out. A grapple eliminates this hesitation. The hydraulic cylinders lock the upper jaw onto the material, creating a secure hold that withstands the bumps and vibrations of a rough job site. This security translates directly into faster cycle times, allowing crews to move more volume per hour than they could with traditional methods.

Minimizing Manual Intervention

Efficiency also stems from keeping the operator in the cab. Without a grapple, ground crews often must stop what they are doing to manually balance heavy debris into a bucket or chain up a log for dragging. This manual intervention halts momentum and diverts labor from other necessary tasks. A grapple allows the skid steer operator to approach a pile, bite down, and move it without assistance. This autonomy keeps the entire crew productive, as ground workers can focus on detailed tasks while the machine handles the heavy lifting.

Mastering Diverse Material Handling

Contractors rarely deal with uniform materials. A demolition site might contain rebar, concrete, wood, and drywall, while a land clearing project involves brush, stumps, and large boulders. The versatility of a heavy-duty grapple shines in these unpredictable environments. The design of the attachment allows it to manipulate objects that a smooth bucket simply cannot handle.

Adapting To Irregular Shapes

The dual-jaw or single-jaw design of a grapple allows it to encompass odd-shaped items. It can pinch a single large boulder or scoop a massive bundle of loose brush with equal effectiveness. This adaptability reduces the need to switch attachments constantly. A contractor can move from tearing down a shed to clearing the resulting debris and then grading the soil, all without leaving the machine. This fluidity is essential for maintaining workflow on sites where the tasks change rapidly.

Sifting and Sorting Capabilities

Many heavy-duty grapples, specifically root and rock grapples, feature an open-bottom design. This slat-style construction provides a distinct advantage over solid buckets. When an operator scoops up a pile of demolition debris or pulled roots, the dirt and small particulate matter fall through the gaps between the tines. This leaves only the target material in the jaws. By leaving the dirt on the job site, contractors save money on disposal fees, as they are not paying by weight to haul away clean fill dirt. It also makes for a cleaner burn pile if the material is destined for incineration.

Reducing Operational Expenses

While the initial investment in a high-quality attachment costs money, the long-term savings justify the expense. Heavy-duty grapples reduce operational costs through labor savings and equipment optimization. By mechanizing the most physically demanding parts of the job, contractors reduce the physical strain on their workforce.

Lowering Labor Costs and Fatigue

Manual labor is one of the highest costs for any contracting business. Moving heavy logs, rocks, or debris by hand is slow, exhausting, and prone to causing injuries. A grapple allows one machine operator to do the work of several laborers in a fraction of the time. This efficiency allows contractors to bid more aggressively on jobs, knowing they can complete the work with fewer man-hours. Furthermore, reducing physical fatigue helps crews maintain higher energy levels throughout the day and the week, leading to consistent productivity rather than burnout.

Decreasing Equipment Wear

Using the wrong tool for the job often damages equipment. When operators force a standard bucket to perform grapple work, they frequently ram piles to secure a full load. This aggressive driving puts unnecessary stress on the skid steer's drivetrain, tires, and loader arms. A grapple allows for a more surgical approach. The operator drives up, clamps down, and lifts. This controlled movement preserves the lifespan of the skid steer and reduces maintenance costs associated with rough operation.

Prioritizing Safety and Site Responsibility

Safety protocols are non-negotiable in modern construction. Heavy-duty grapples contribute significantly to a safer work environment by creating distance between workers and hazardous materials. The mechanical advantage of the hydraulic jaws removes the need for human hands to touch sharp, heavy, or unstable debris.

Removing Workers From Harm's Way

Handling demolition debris often involves exposure to rusty nails, jagged metal, and heavy concrete that can crush fingers or toes. By utilizing a grapple, the operator handles these hazards from the protection of a reinforced cab. This separation drastically reduces the likelihood of lacerations, puncture wounds, and crush injuries. Additionally, the secure clamping force prevents heavy objects from rolling off the pile and striking workers nearby, creating a safer zone of operation for everyone on site.

Enhancing Environmental Cleanup

Environmental responsibility aligns with safety. A grapple allows for precise sorting of materials, which facilitates recycling. An operator can pick out metal beams for the scrap yard, separate untreated wood for chipping, and isolate concrete for crushing. This level of sorting is difficult and time-consuming to perform by hand or with a standard bucket. By diverting recyclable materials from the landfill, contractors save on dumping fees and position their company as an environmentally responsible choice in the market.

Elevate Your Contracting Business

The right equipment is a force multiplier for any construction or landscaping business. Heavy-duty grapples offer a unique combination of power, precision, and safety that standard buckets simply cannot match. By reducing manual labor, speeding up cycle times, and enabling precise material handling, these attachments pay for themselves through increased efficiency and reduced operational costs.

Express Steel understands the key benefits of heavy-duty grapples for contractors and offers a wide variety of American-made skid steer attachments to simplify your toughest tasks. Whether you are clearing a lot or managing a demolition site, our tools provide the power and efficiency needed to ensure every project finishes on time and under budget. Explore our products and maximize the capabilities of your equipment today.